Technical Parameter

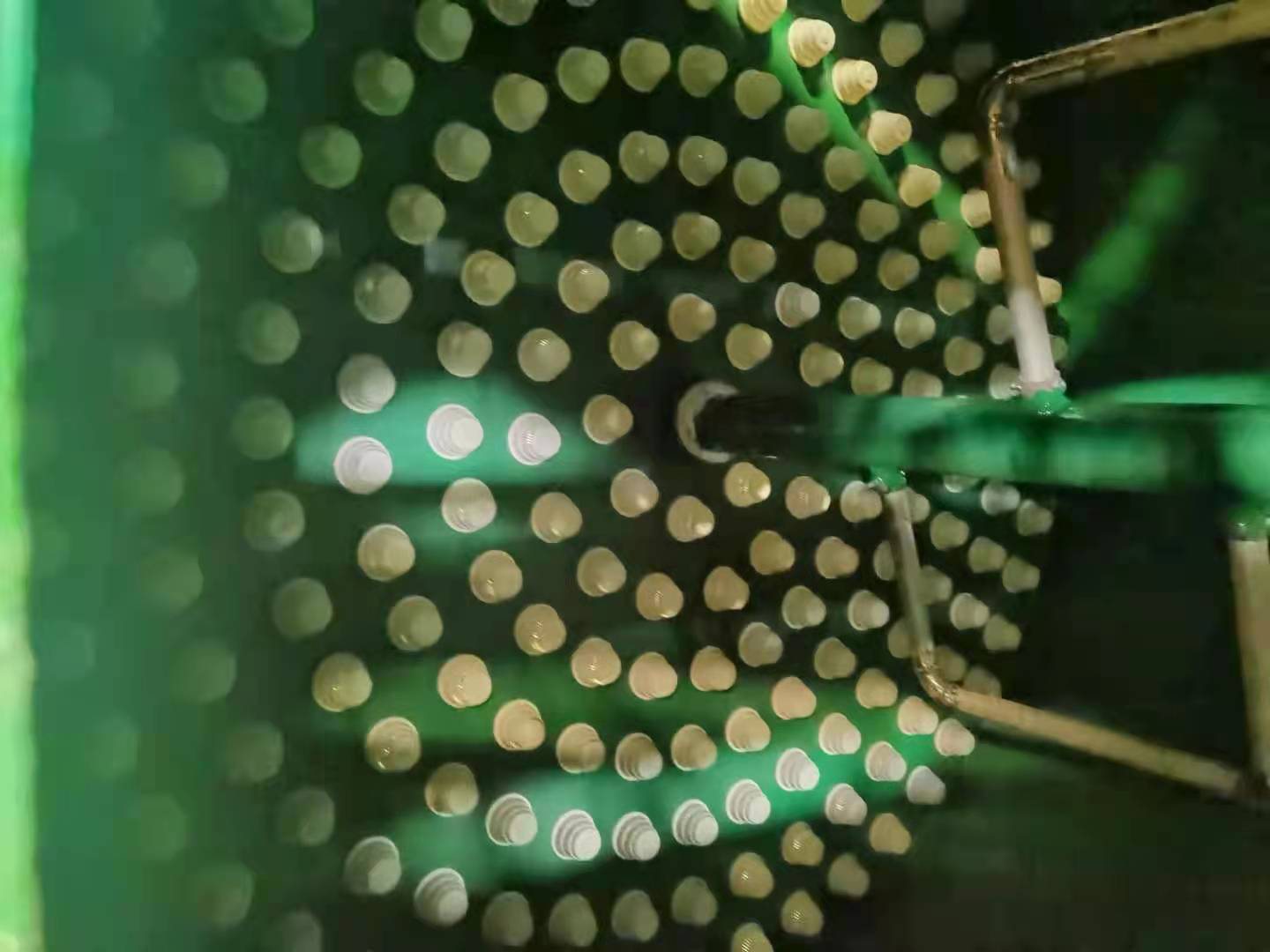

Pazasi pane paramita yewalnut shell strainer

Nzvimbo dzekushanda parameters:

Kumanikidza kushanda: ≤0.6MPa; Inlet mvura inodzvinyirira: ≥0.4MPa;

Backwashing inlet water pressure: ≥ 0.15MPa; Musiyano wekupinza uye kubuda kwekumanikidza: 0.1-0.2MPa

Operating parameters inoshanda mode:

Pressure type; Operation mode: mvura inoyerera kubva kumusoro kusvika pasi; Sefa yekumhanyisa: 20-25m / h; Kushanda kutenderera: 8-24h;

Backwash mode: mvura backwash;

Kushandiswa kwemvura yekudzokera shure: 1-3%; Simba rekudzokera shure: 4-15l / s · m2;

Backwash nguva: 20-30min; Backwash yekuwedzera mwero: 30-50%

Kurapa maitiro:

Coarse filter mvura: mafuta, ≤100mg / L, SS, ≤50mg / L;

Effluent: mafuta, ≤10mg/L, SS, ≤10mg/L;

Fine filter mvura: mafuta, ≤20mg / L, SS, ≤20mg / L;

Effluent: mafuta, ≤5mg/L, SS, ≤5mg/L;

Matanho maviri-matanho emvura anotora: mafuta, ≤100mg / L, SS, ≤50mg / L;

Effluent: mafuta, ≤5mg/L, SS, ≤5mg/L;

Intercepting simba 6-20kg/m3

Chigadzirwa mukana weWalnut Shell Sefa

1. Pamusana pemhando ye hydrophilic kwete mafuta-philic, iyo walnut shell inokurudzirwa kuti ikwikwidze mumwe nemumwe mumusangano kana backwashing, kuitira kuti desorption simba rive rakasimba, simba rekuzvarwa patsva rakasimba, kugadzikana kwemakemikari kwakanaka, kunobatsira kugadzikana kwenguva refu kwekushanda kwesefa.

2. Iyo walnut shell fiter midziyo inotora yakadzika mubhedha kusefa, iyo inogona kuvandudza zvakanyanya kugona kwekupinza.

3. Kushandiswa kwe anti-blocking maze pachinzvimbo cheyakajairika yekugovera mvura skrini, kudzivirira sefa iri mukuita basa nekuwedzera kwenguva kana shanduko yemhando yemvura uye blockage chiitiko.

4. Kushambadza kwakasimba uye huwandu hukuru hwekubiridzira kusvibiswa;

5. Oiri kunyudzwa kuramba, kaviri mhedzisiro kubviswa kwemafuta uye yakamiswa nyaya;

6. Kuvandudza nyore, kugeza musana pasina mushonga;

7. Inogona kubatanidzwa mune zvakatevedzana kana zvakafanana.

Applications

1. Kurapa kwetsvina yemafuta kubva pasi uye Marine mafuta minda, petrochemical uye metallurgical minda.

2. Kurapwa kwetsvina ine mafuta muzviteshi, wharves nemadepo emafuta.

3. Kurapa kwezvikepe uye mamwe tsvina yemafuta.

4. Inoshanda kune kudzokorodza uye kusefa kurapwa kwemafuta etsvina uye mamwe ane mafuta tsvina yetsvina masisitimu musimbi nesimbi, metallurgical industry, marasha indasitiri.

5. Inokodzera kusefa kwakanaka kwemafuta emunda reinjection mvura ine vhoriyamu yemvura yakakura, mvura inogadzirwa kubva kune offshore mafuta papuratifomu uye mvura inodzoserwa kubva kune inopisa kudzoreredza boiler yeheavy oil field.

6. Inokodzera kurapwa kwefiltration uye kurapwa kwepamusoro kwekutonhora kutenderera kwemvura mumagetsi emagetsi, kunatsa uye petrochemical plant.